A

AIA CES Credits

AV Office

321M Fayerweather Hall

Abstract Publication

415 Avery Hall

Academic Affairs

400 Avery Hall

Academic Calendar, Columbia University

Academic Calendar, GSAPP

Admissions Office

407 Avery Hall

1172 Amsterdam Avenue

New York, New York 10027

Advanced Standing Waiver Form

Must be printed and returned to 400 Avery Hall

Alumni Board

Alumni Office

405 Avery Hall

1172 Amsterdam Avenue

New York, New York 10027

Architecture Studio Lottery

Assistantships

Avery Library

300 Avery Hall

1172 Amsterdam Avenue

New York, NY 10027

Avery Review

Avery Shorts

B

Black Student Alliance at Columbia GSAPP

Building Science & Technology Waivers

Bulletin Archive

C

Career Services

300M Avery Hall

Columbia Books on Architecture and the City

Commencement

Communications Office

415 Avery Hall

Conversations podcast

Counseling and Psychological Services

Courses

Credentials Verification

Credit Transfer

Cross Registration

D

Dean’s Letter

Dean’s Office

402 Avery Hall

1172 Amsterdam Avenue

New York, NY 10027

Development Office

404 Avery Hall

Directory of Classes (All Columbia University)

Disability Services

Dodge Fitness Center

3030 Broadway Dodge

Dual Degree Program Requirements

E

End of Year Show

Events Office

415 Avery Hall

External Funding Sources

F

Faculty Directory

Feedback

Finance Office

406 Avery Hall

Fitch Colloquium

Future Anterior Journal

G

GSAPPX+

Grades

Graduation

Graphics Project

H

Honor System

Human Resources

Hybrid Pedagogy Resources

I

IT Helpdesk Ticket, GSAPP

IT Office, GSAPP

IT, Columbia University (CUIT)

Identity

International Students and Scholars Office (ISSO)

N

News and Press Releases

Newsletter Sign Up

Non-Discrimination Statement and Policy

O

Onera Prize for Historic Preservation

Online Admissions Application

GSAPP Admissions 407 Avery Hall

Output Shop

116 Avery Hall

1172 Amsterdam Avenue

New York, NY 10027

Ownership of Student Work Policy

P

Paris Prize, Buell Center

Paul S. Byard Memorial Lecture Series

Percival & Naomi Goodman Fellowship

Plagiarism Policy

Policies & Resources

Press Releases

Publications Office

415 Avery Hall

1172 Amsterdam Avenue

New York, New York 10027

R

Registration

Registration: Add / Drop Form

Room Reservations

S

STEM Designation

Satisfactory Academic Progress

Scholarships

Skill Trails

Student Affairs

400 Avery Hall

Student Awards

Student Conduct

Student Council (All Programs)

Student Financial Services

Student Health Services at Columbia

Student Organization Handbook

Student Organizations

Student Services Center

205 Kent Hall

Student Services Online (SSOL)

Student Work Online

Studio Culture Policy

Studio Procedures

Summer Workshops

Support GSAPP

ASSEMBLING ALL SORTS

Parametric digital design tools and computer- aided manufacturing have enabled a non- uniform, curvilinear and mass-customized architecture. While this conceptual plasticity of the first digital turn has relieved architects of the monotony of the mass-produced detail, the apparent freedom of digitally fabricated architecture still remains bound to industrially produced, standardized components (blanks, bars, bricks and sheet stock) or isotropic plastics (3D printing, themoforming). Designs are generated in a digital world of infinite possibility, and are wastefully materialized into a world constrained by the 4x8 sheet.

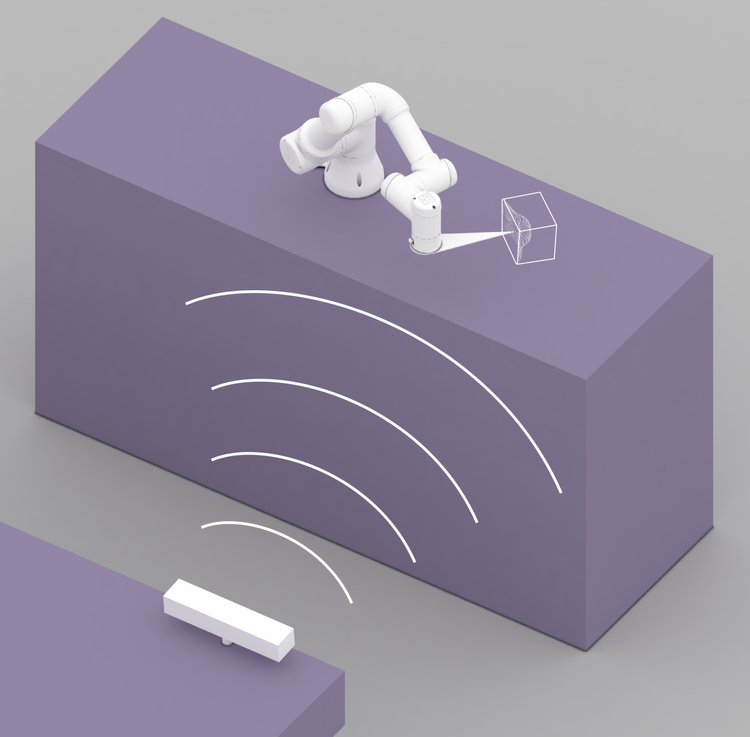

The assimilation of digital information and material properties (made possible by algorithmic design and robotic fabrication) has the potential to increase resource efficiency, while enriching the tactile, visual and performative aspects of architecture through the controlled application of material variation. In practice, however, this “digital materiality” is often limited to components which are dimensionally uniform and selectively obtained—the uninformed brick3 or grain of sand4 already bear some resemblance to the pixel.

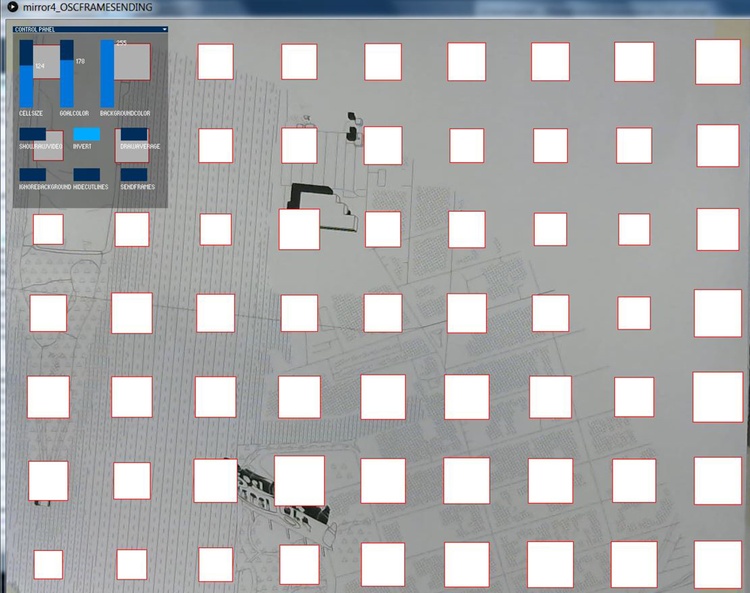

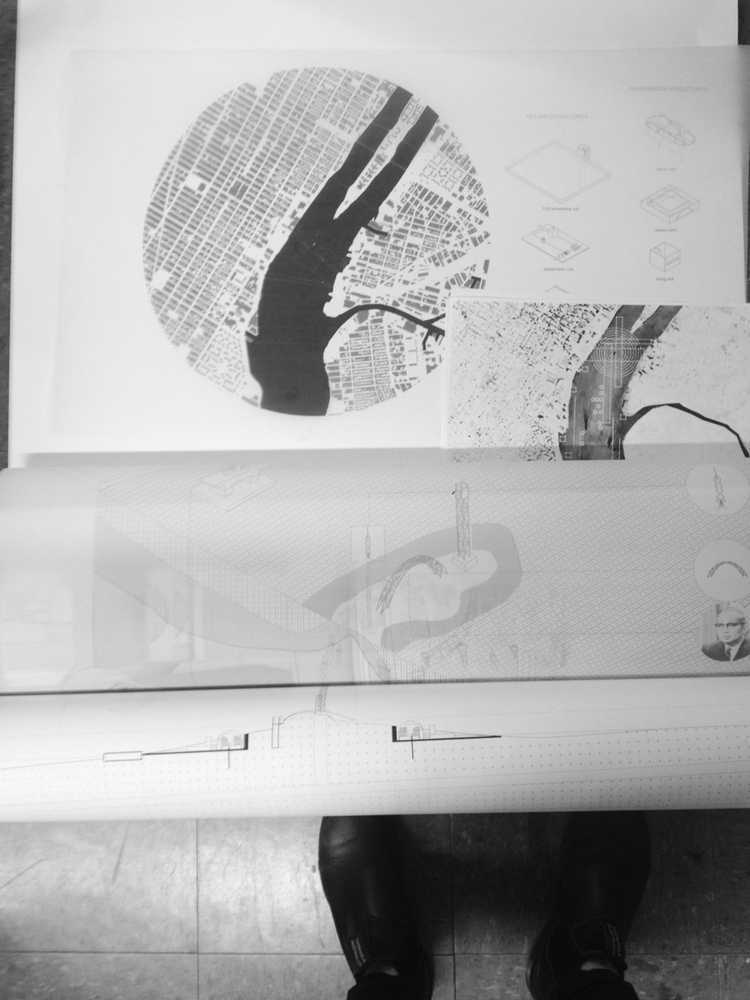

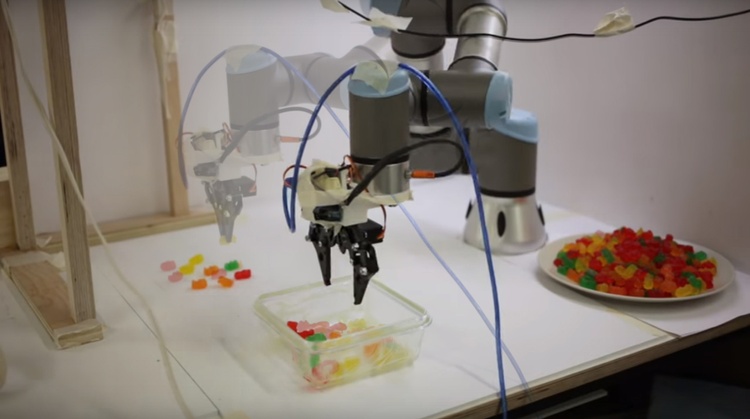

This seminar will focus on creating details and assembly techniques which derive their non uniformity, in part, from irregular, “found” building materials. We will develop strategies for digitizing such materials, and methods of programming which allow for these digitized properties to be incorporated into the design. The course will involve the creation of digital and physical study models, and the development of a prototypical robotic assembly technique using the school’s UR3 robot. Course size is limited, and previous exposure to Grasshopper and/or some programming (Java/Python, etc) will be helpful for students.

Some past student documentation can be found on the course sites:

- http://assemblingallsorts-fall16.tumblr.com/

- http://assembingallsorts-sp16.tumblr.com/

300 AVERY HALL

W 9 AM - 11 AM

FULL SEMESTER

TECH ELECTIVE

63398

| Course | Semester | Title | Student Work | Instructor | Syllabus | Requirements & Sequence | Location & Time | Session & Points | Call No. |

|---|---|---|---|---|---|---|---|---|---|

| ARCH4686‑1 | Spring 2018 |

Assembling All Sorts

|

Ryan Luke Johns | Syllabus |

Tech Elective-Fabrication |

505 Avery

W 7 PM - 9 PM

|

Full Semester

3 Points

|

87996 | |

| ARCH4686‑1 | Spring 2017 |

Assembling All Sorts

|

Ryan Luke Johns | Syllabus |

Tech Elective - Fabrication |

505 Avery Hall

W 7 PM - 9 PM

|

Full Semester

3 Points

|

92846 | |

| ARCH4686‑1 | Spring 2016 |

ASSEMBLING ALL SORTS

|

|

Ryan Luke Johns |

TECH ELECTIVE- FABRICATION (1.5) |

504 AVERY

TU 11 A M - 1 PM

|

SES B 3/7-4/22

1.5 Points

|

60837 |